- FIFO and FEFO strategies in warehouse logistics

- FEFO and FIFO in warehouse logistics: main advantages

- FIFO and FEFO disadvantages: what to consider

- LIFO principle: what it is and for what products it is suitable

- What are the benefits of using the LIFO strategy

- LIFO method disadvantages

- How to make warehouse operations effective with inventory management strategies

- The FEFO, FIFO, and LIFO methods in warehouse logistics comparison table

- Frequently asked questions on warehouse management strategies

- Conclusions: FEFO, FIFO, or LIFO — which goods selection strategy to choose

Well-organized warehouse logistics is an important competitive advantage for a business that manufactures or sells goods. The warehousing process efficiency depends on how freight moves through a warehouse, how their accounting is organized, and what method for it is used. Logistics digitization has changed the way how warehouses and logistics centers operate. Companies use Warehouse Management Systems (abbreviated as WMS) in their workflow to keep accurate records of goods, control their shelf life, contain information about their location in a storage facility, optimize space usage. You can find more information about what WMS is in our article.

However, a properly organized warehouse space isn’t enough. To use WMS effectively, it is necessary to define the goods processing principles. There are 3 main strategies — FIFO, FEFO, and LIFO — in warehouse logistics. In this article, you will find out what these methods are, for which product group each is used, and how to choose the appropriate one for a particular storehouse.

FIFO and FEFO strategies in warehouse logistics

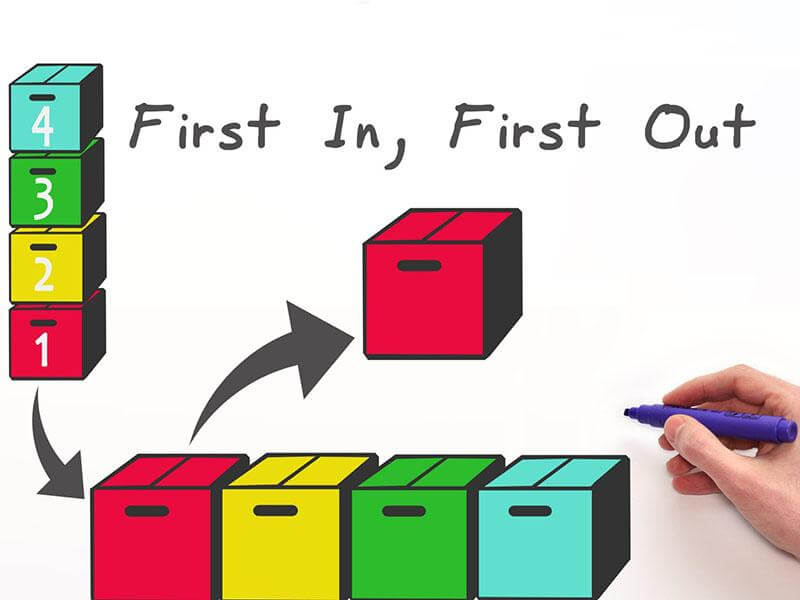

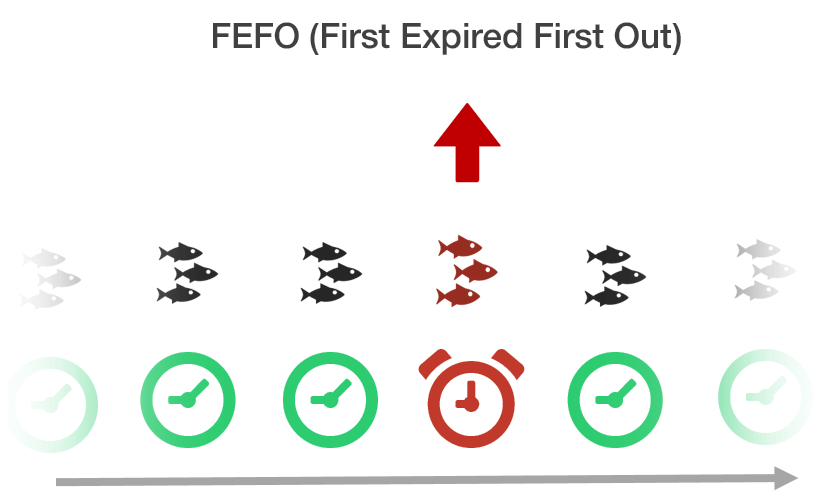

The most popular approaches to goods selection in a warehouse are FIFO and FEFO. These are acronyms. FIFO stands for First In, First Out, and the meaning of FEFO is First Expire, First Out.

The FIFO principle implies that the goods that were stocked in a warehouse first, will be processed also first. For example, two consignments of canned goods entered a warehouse. One of them arrived at the beginning of the month, the other one — at the end of the month. According to the FIFO principle, when the order is received, the canned goods that arrived in a warehouse early in the month will be shipped out.

When using the FEFO principle, the main priority for shipment is the expiry date, not the arrival time. That means the goods whose shelf life expires first are processed also first. For example, two consignments entered a warehouse. The first was received at the beginning of the month with an expiry date of 30 days. The second one arrived in a warehouse at the end of the month with an expiry date of 15 days. The FEFO approach implies that freight with an expiry date of 15 days, will be procsses first, although it entered a warehouse later.

These methods are similar to each other since in most cases goods that have just arrived in a warehouse have a longer shelf life than older stocks.

These approaches are used for goods that can’t be stored for a long time. They are foodstuff, medicines, FMCG, and other products that have to be sold as soon as possible. Seasonal goods, fashion, and consumer electronics are among them, as the longer they are stored, the higher probability that they become obsolete and aren’t sold.

FEFO and FIFO in warehouse logistics: main advantages

- Obsolete stock reduction. When goods become obsolete and lose their appeal to consumers, a business can suffer serious losses. The FEFO and FIFO strategies decrease the chances that the products aren’t sold before the expiration date and become outdated.

- Spending cuts for warehouse logistics. If the goods aren’t stored in a warehouse for a long time, the warehouse cost will also be lower.

- Customer satisfaction rate increase. Since the stocks are actively rotated in a warehouse, customers receive less likely obsolete or poor-quality goods. This increases consumer confidence in a company.

- Reducing the inflation impact on business. Inflation is an ongoing process. The production costs are becoming higher, and so selling stocks that were produced earlier and whose production cost is lower contributes to the business profitability.

FIFO and FEFO disadvantages: what to consider

- An accurate product tracking system is required. FIFO/FEFO implementation is impossible to imagine without accurate stock tracking. So a company has to purchase and maintain a proper system for tracking all goods that arrive and are shipped from a warehouse.

- Warehouse space has to be well-organized. To use FIFO and FEFO strategies effectively, a storehouse has to be carefully organized. Goods that are stored in a warehouse for a long time, should be placed next to the shipping area. This requires large storage space and specialized handling and shelving equipment.

- It’s difficult to scale up a business. When a business starts to expand, it needs more storage space. It can be difficult to process large amounts of information about goods and to control their shelf life in different warehouses.

- Higher taxes. Since the use of FIFO and FEFO minimizes inflation, it leads to profit growth, so taxes increase as well.

LIFO principle: what it is and for what products it is suitable

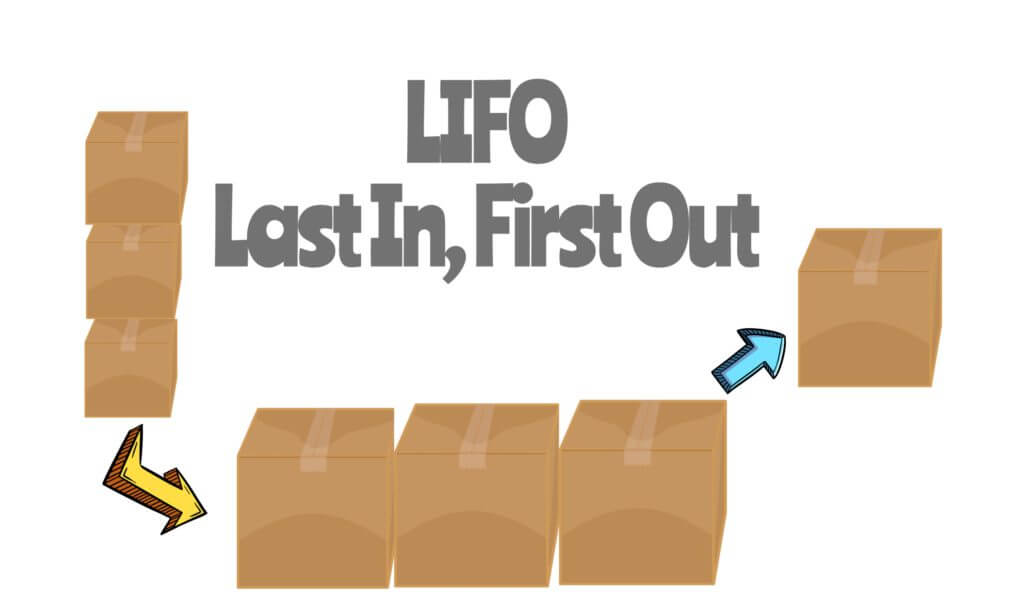

The meaning of LIFO is Last In, First Out. It is the exact opposite of the FIFO and FEFO principles. In this case, goods that arrived in a warehouse most recently must be processed and processed first. The LIFO strategy is similar to the principle of a stack of plates, where you can take a plate from the middle of the stack only by removing the ones on the top.

This approach is widely used for fragile products, which it isn’t desirable to move through a warehouse too often, as well as for homogeneous goods such as bulk building materials. They have a long shelf life and become obsolete very slowly. It enables the entire warehouse space usage (especially if it is limited) and saves time on freight handling operations.

What are the benefits of using the LIFO strategy

- Warehouse space optimization. The LIFO approach implies a new consignment of goods is placed on top of old stocks in a warehouse. In this way, less storage space is needed, as a stock rotation isn’t required.

- Cost-revenue comparison. LIFO allows easy comparison of recent сosts and profits. When production costs increase, so does the cost of goods. Thus, a business has a clear understanding of its income.

- Taxes reduction. With a more accurate profit estimation, a company will overestimate its profits and underestimate the cost of the goods less likely. Therefore, its revenue will correspond to reality and taxes will be less.

- Fewer write-offs. If the market value of a product fluctuates, it is more profitable to sell goods that were produced earlier when prices fall. Therefore, losses are reduced.

LIFO method disadvantages

- Obsolete stocks remain. Obsolete stocks can never be sold. Therefore, this method is recommended only for products with a long shelf life.

- Loss of profits during inflation. During inflation, a company that uses the LIFO method decreases the reported profits. This may reduce the company’s attractiveness to investors.

- Stock quantity underestimation. The reported stock quantity is generally underestimated because it is based on older costs. As a result, the company’s working capital may appear worse than it is.

- Difficulties in entering the international market. Although LIFO is now a common practice, it is not permitted in all countries. Therefore, companies that want to achieve international breakthroughs should use FIFO.

How to make warehouse operations effective with inventory management strategies

First of all, it is necessary to place the goods correctly in a warehouse. The FIFO process implies that the goods that arrived in a warehouse first are located next to the shipping area. Using the FEFO method, companies place goods with short expiry dates ahead, and goods with long storage terms are stored in the depths of a warehouse. All of this requires large storage space and proper organization. By LIFO, the product placement strategy is much simpler — new batches are placed on top of the old ones. Therefore, the loading and unloading areas are located nearby.

For effective warehousing operations, a company has to purchase special storage equipment. For FEFO and FIFO methods, gravity flow racking is usually used. By gravity, the loads are moved from the unloading zone to the shipping area. It enables optimizing the use of handling equipment. Shuttle racking systems are applied only by the LIFO approach. They allow using the entire storage space and are needed for large consignment processing.

Drive-in pallet racks are suitable for LIFO, as palletized loads are placed in the depth of the structure. However, a company should consider goods can’t be damaged during shipment, so the solution can’t be used for all product groups. Push-back racking that combines the principles of the drive-in and gravity flow racking is generally applied by the LIFO approach, but they are suitable for FIFO and FEFO strategies as well.

The FEFO, FIFO, and LIFO methods in warehouse logistics comparison table

We described how FEFO, FIFO, and LIFO are used in practice, what are the pros and cons of each principle, and for which product groups they are suitable. Below, you can get acquainted with a comparative table where methods meaning and essence are presented, and in which situations they should be applied.

| Name | FEFO | FIFO | LIFO |

| Meaning | First Expire, First Out | First In, First Out | Last In, First Out |

| Method essence | This method ships out the goods with shorter expiration dates first. | The goods that entered a warehouse first will be shipped out first. | The products that were received most recently, will be moved out first. |

| When used | The approach is suitable for processing perishable goods in different consignments. | It is used in situations when goods can quickly become obsolete, are popular only in a particular season, and have a limited shelf life. | The principle is used for homogeneous goods, mostly for large consignments. |

| For which product group is suitable | Foodstuff, medicine, cosmetics, any product with a limited shelf life. | Same as for FEFO, + consumer electronics, seasonal products, fashion; any products that quickly become obsolete/out of date. | Building materials, chemicals, bulk freights, raw materials; products with unlimited or long shelf life. |

If your company hasn’t yet decided on an approach to the goods selection in a warehouse, it can outsource these tasks. 3PL providers deal professionally with freight storage and processing. WareTeka cooperates with 30+ logistics providers throughout Ukraine. We’ll select for your company a contractor that works with the right product segment, has well-organized logistics, and provides efficient goods processing taking into account your freight specifics, commodity neighborhood, and business tasks.

Frequently asked questions on warehouse management strategies

FIFO and FEFO estimate stocks more accurately, as by using these methods, goods that were purchased earlier are sold first. The stocks that just enter a warehouse are purchased at the relevant market prices. This provides a clear understanding of the company’s profit. By using the LIFO approach, stocks are much more difficult to estimate, since goods that were purchased long ago were bought at a price lower than the current one.

The LIFO method isn’t permitted by International Financial Reporting Standards (IFRS) because it can distort information on a company’s profitability. Therefore, countries that adopted IFRS standards may refuse to cooperate with companies that use this approach.

Except for the methods mentioned above, BBD (Best Before Day) and FPFO (First Product, First Out) strategies are used. In the same way as FIFO, FEFO, and LIFO, such solutions are applied for handling certain product groups.

Conclusions: FEFO, FIFO, or LIFO — which goods selection strategy to choose

There is no universal solution for warehouse management. However, there are some factors to consider when selecting a strategy. One of the most important is the product type. FEFO and FIFO strategies are suitable for goods that have a limited shelf life and need to be sold quickly. If not, goods spoil and a company loses its revenue. The LIFO approach is generally optimal for products with a long shelf life. However, it is necessary to analyze consumer demand and the market situation. The FEFO and FIFO methods are used to process goods whose cost and demand are relatively stable. For products, whose prices are volatile and new units are more popular among customers, LIFO is preferred.

To use any of the strategies most effectively, a company needs established warehouse logistics. This business activity requires many resources therefore warehouse logistics outsourcing is the optimal solution for both small companies and enterprises that are expanding. In this way, the business gets a ready-made solution of goods storage and processing and can focus on higher priorities.