- What is a cross-docking practice in logistics?

- Why do logistics operators use X-docking in their routine warehousing processes?

- What does cross-docking workflow look like?

- What is the difference between cross-docking terminals and warehouses?

- What are the cross-docking modifications?

- Conclusions: What companies should try a cross-docking service

Traditionally, the supply chain in logistics consists of manufacturing, goods transportation to a warehouse, storage, assembling, and dispatching to a retail outlet or end consumer. However, this method of supply chain management is inappropriate for some companies. For example, for a business that works with different suppliers and perishable goods. It needs to build a fast and advantageous process without additional investment in warehouse infrastructure and staff. It makes sense to try a cross-docking service from a 3PL provider in such a situation. This service allows organizing orders assembling and their delivery without long-term storage.

In this article, WareTeka explains how cross-docking enables a business to optimize logistics costs and speed up delivery to an end customer.

What is a cross-docking practice in logistics?

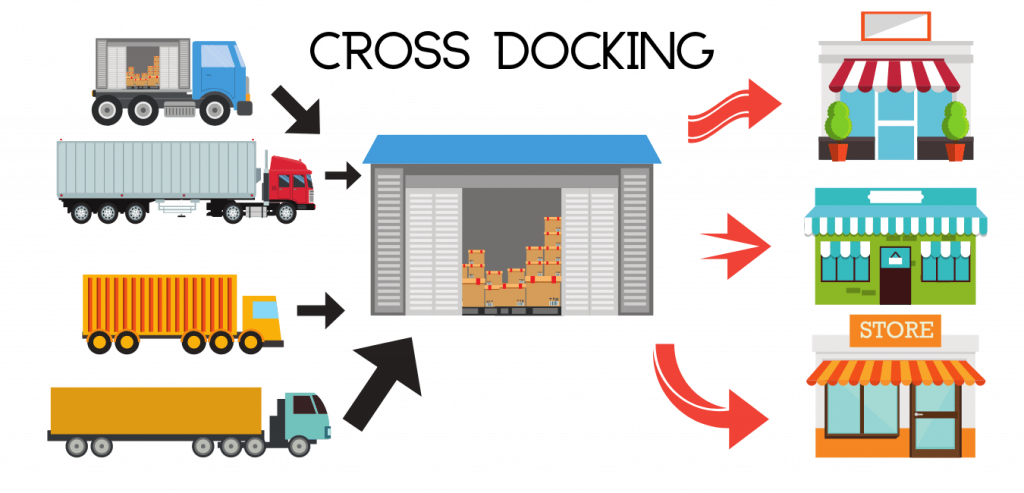

Logisticians are constantly developing methods to increase supply chain efficiency. Cross-docking is one of them. This term refers to the process of receiving and shipping goods without long-term storage. Goods are placed in a warehouse that serves as a transit point. Here, warehouse workers collect them from different suppliers, pick them up if necessary, and load them into cars. Shipment and delivery of goods are agreed on time, so there is no need to store freight.

Cross-docking simplifies a company’s logistics processes and allows to track efficiency at any link of the supply chain. It also eliminates considerable warehousing costs. A cross-docking warehouse is designed to handle incoming and outgoing goods flows as efficiently as possible, and has a large number of through gates. The receiving of goods is arranged so that freight can be easily transported from the reception area to the expedition area for delivery to consumers. It also eliminates costs for unnecessary services and warehousing. Also, the fact that goods are delivered to an end consumer very fast reduces the risks of their spoilage. Thus, a business suffers fewer losses in goods transportation.

Cross-docking allows faster delivery, which increases customer loyalty. In addition, part of the product value includes transportation and storage. Since goods are not stored in a warehouse for long-term storage, and a business does not pay for this stage. So the value of the final product is also reduced. This makes the product more attractive to consumers and becomes an important competitive advantage.

Why do logistics operators use X-docking in their routine warehousing processes?

Cross-docking enables supply chain optimization, delivery terms reduction, and work with large flows of goods with minimal staff involvement. This service is needed by companies that do not have their warehouse. By using this approach, such enterprises reduce warehouse rental and maintenance costs. However, it is worth considering that if a business does not have its transport fleet, it cannot organize a cross-docking process on its own. In such a case it makes sense to order this service from a 3PL provider.

Using cross-docking is effective when a product is delivered in small volumes but with a varied assortment. In the cross-docking terminal small batches can be consolidated into a large one and sent to one receiver. This method is also used when goods from several suppliers have to be shipped to different receivers. This allows gaining time by processing a large number of orders, which is especially relevant during peak sales season.

Due to its features, cross-docking enables to organize logistic processes as efficiently as possible in dealing with such types of freight:

- perishable foodstuffs (meat, dairy, vegetables, fruit);

- mass consumer goods;

- orders which are assembled for fast delivery;

- high-quality products that do not need to be checked in a cross-docking terminal;

- products with a fixed sales date.

For these types of goods, high speed is important for delivery, processing, and dispatching to a consumer. Because products are not stored in a warehouse, the risks associated with storage, such as spoilage, damage, or loss, are reduced. Therefore, by cross-docking outsourcing, a business can be sure that its products arrive in time without losing quality.

What does cross-docking workflow look like?

The selection of a cross-docking workflow is based on how the product is delivered, what the company’s requests are, and in what condition it has to leave a terminal. There are currently two methods of cross-docking:

- One-stage. This type of cross-docking means that the goods in pallets are brought to a warehouse. The order is already packed to exclude access by unauthorized persons and has a marking, order number, and the name of a receiver. The goods are receipted, in the same condition placed in the expedition area, dispatched, and shipped to the receiver.

- Two-stage. Freight is placed in the assembling area before loading it in a car for delivery. After receiving goods are dissolved and completed with products from other suppliers. The ready-made order is dispatched and delivered to a receiver.

In both cases, the goods are not stored for a long time. The handling of goods in one- and two-stage cross-docking has certain steps. They differ, but some of them are mutual for both workflows.

A cross-docking workflow, which takes place in one stage, looks like this:

- Transshipment — goods without storage are shipped to another vehicle and sent to a receiver.

- Deconsolidation. Freight must be shipped for delivery in different destinations; it is prewrapped, dispatched, and shipped in different directions.

Two-stage cross-docking consists of such processes:

- Reconsolidation. The goods are taken to a warehouse, sorted according to the already collected batches, unloaded to different transport facilities, and sent to an end consumer.

- Consolidation. Freight is received from different suppliers, unloaded, and formed in a single shipment. Then it is shipped and delivered to an end customer.

With one- and two-stage cross-docking, a sub-sorting of goods is possible. This is the process of order assembling when received goods are added to goods that were received earlier.

What is the difference between cross-docking terminals and warehouses?

Cross-docking terminals, unlike warehouses, are designed not to store goods but to transform freight flows. To ensure goods receiving efficiency and the high speed of orders assembling, they have a specific layout and equipment.

The width of the cross-docking terminal should be one-third of its length. Such kind of construction allows installing loading and unloading docks and convenient drive-in to the warehouse with dock shelters and dock levelers on both sides. This will enable to separate incoming or outgoing freight flows. One gate should be located for every 300-500 m². Due to its length, I-, L-, H-, U-, T-shaped premises are used for cross-docking. The terminal space must have a minimum of supporting сonstructures and all necessary loading equipment.

The implementation of the Warehouse Management System enables high productivity of a cross-docking terminal in handling freight flows. Information about incoming or outgoing goods enters the system by reading RFID chips or barcodes. In this way, warehouse staff can monitor goods’ movement and errors in real-time. It also speeds up order assembling. Drivers of transport facilities receive notifications when and to which gates they have to drive up. All these measures allow establishing of clear dispatching and loading timings. Unlike a standard warehouse, time overlays are unacceptable in a cross-docking terminal.

What are the cross-docking modifications?

Apart from “classical” cross-docking, there are other logistics services based on the principle of processing orders without long-term storage. They are the same cross-docking but with some features to achieve specific customers’ goals and purposes.

Break Bulk cross-docking service (BBXD) implies that goods are delivered to the 3PL distribution center in any condition. The freight from different suppliers is dissolved, and according to the customer’s request consolidated and sent to a receiver. This is the optimal solution for retail networks, which need to organize quick delivery of products (including also imported) in their shops without losing quality. The service also enables delivery routes and trucks usage optimization.

Another cross-docking modification is flow-through. The feature of a flow-through service is that it is made for sales direction. It is a synthesis of cross-docking, BBXD, and fulfillment. The incoming flow can include large and small consignments, which will be modified into ready-made orders to specific receivers. A business transmits to a 3PL provider a common list of goods and indicates their weight characteristics. By using this information, a provider selects the type of packing and calculates the service price. Also, a company informs which goods from the common list will go to specific orders and names of receivers. A workflow of cross-docking and flow-through are similar, but flow-through may include more additional services — putting in promotional materials and guarantee cards, returns processing, etc. This service is used by importers, exporters, distributors, retailers, e-commerce.

We present a table with comparative characteristics of different cross-docking modifications.

| Modification | Sales direction | Business segments | Goods receiving condition | Peculiarities |

| Cross-docking | B2B | Manufacturers, distributors, retail networks | Mono or mix pallets | Goods in pallets arrive at the terminal, and in the same condition are loaded on transport facilities |

| BBXD | B2B | Manufacturers, distributors, retail networks | Mono or mix boxes, mono or mix pallets, pieces, outsize loads | Goods in boxes or pallets arrive at the terminal, goods from different conditions are consolidated into a separate shipment and dispatched by different transport facilities |

| Flow-through | B2C | eCommerce | Mono or mix boxes, mono or mix pallets | Goods in boxes or pallets arrive at the terminal, products are picked up individually and sent as single orders to end consumers (Internet shop customers) |

Conclusions: What companies should try a cross-docking service

The implementation of cross-docking allows optimizing the logistics of a company and reducing product value by minimizing warehousing costs. A well-organized process speeds up delivery, enables a business to send perishable products over long distances, and manages goods turnover properly even in a peak season. Cross-docking is suitable for retail networks, supermarkets, logistics and outsourcing companies, auto businesses, and any companies that need continuous supply flow.

A business should choose a reliable 3PL provider to get a high-quality cross-docking service. It needs to have a sufficient transport fleet and necessary infrastructure; a cross-docking terminal must be automated. The service price depends on the type of freight, volumes of supplies, the number of stages in the chain, the need to provide additional services.